TOPCON

SOLUTIONSWhy Our Customers Choose Us

With our commitment to “Made in Japan” manufacturing,

we have realized in-house integrated production.

Based on TOPCON's world-class expertise, we have combined our advanced ultra-precision polishing and optical thin-film coating technologies, and have a framework in place that enables us to respond across our global supply chain.. With the ability to procure metal components and electronic circuit boards in-house, the framework we have established allows us to handle prototypes starting from one unit. We provide optical components through integrated production that spans processing, assembly and evaluation, and have been highly praised by our customers for the superior cost performance that we have gained through VA, TP and improvement activities.

* For optical components, we can accommodate everything from arranging for glass materials to completion as well as the production of optical modules by assembling various components in accordance with your request.

TOP QUALITYHigh Quality/Wide Variety/Small Lots

- We accommodate the production of minimum lots of optical lenses, prisms and optical modules starting with one unit

- Through the integrated production of optical lenses, consistency in our manufacturing process is maintained, making it possible to realize high precision and stable quality

Advantages of In-House Integrated Production

-

- Preservation of high-precision quality

- Managing the entire manufacturing process internally makes consistency in quality and the stable supply of high precision products possible

-

- Cost reductions

- Without the need for outsourcing, the cost of logistics and negotiating with external contractors can be reduced

-

- Prompt response

- This arrangement helps us improve our flexibility to respond immediately to any issues or specification changes that may occur in the manufacturing process

-

- Safeguarding of intellectual property

- Retaining manufacturing technology and expertise completely in-house makes it possible to safeguard the intellectual property of firms

- Can you handle special lens shapes?

- What is the state of your quality control system during the manufacturing process?

- How do you approach quality assurance for lenses used in environments where durability is required?

- Can you provide consistent support from the product design to manufacturing stages?

- Do you have a production framework in place that can accommodate fluctuations in demand?

- Are you carrying out initiatives for sustainable manufacturing processes?

- What kind of initiatives are you implementing in striving to improve product quality?

Needless to say, we have the answers and solutions to all these questions!

Well-equipped facilities that underpin the reliability of 150,000 lenses produced per month

We possess cutting-edge manufacturing equipment and high-precision inspection devices for optical lens production.

With these, we realize strict quality control and stable product supply, and provide high-precision optical lenses.

-

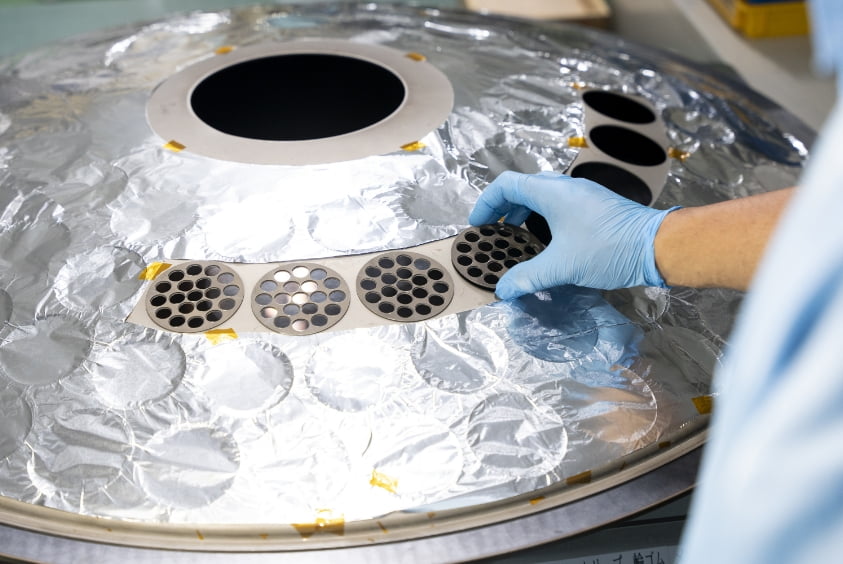

Polishing line We have over 80 polishing machines installed, enabling us to handle optical lens production of 100,000 to 150,000 units per month. We possess equipment capable of accommodating a wide variety of products and shapes. We also place strong emphasis on processing accuracy in order to meet strict quality standards, and supply high-quality lenses on a stable basis.

-

Ultrasonic cleaners As we prioritize environmental protection, we employ spindle-drying ultrasonic cleaners. These enables us to clean and dry products without the use of organic solvents (alcohol). Through successes in ensuring stable quality and mitigating the burden on the environment, we are working towards achieving a sustainable manufacturing environment.

-

High-precision evaporator This dedicated device is capable of processing ultra-wide band anti-reflection and high-reflection low-scattering metal mirrors (Al, and AgAg). Our proprietary control software allows us to maintain stable coating accuracy. Additionally, we possess a UH 4150, Cary 6000 i, and USPM RU W, which enable us to evaluate optical characteristics in fine wavelength ranges. With these, we are realizing the supply of higher-precision products.

-

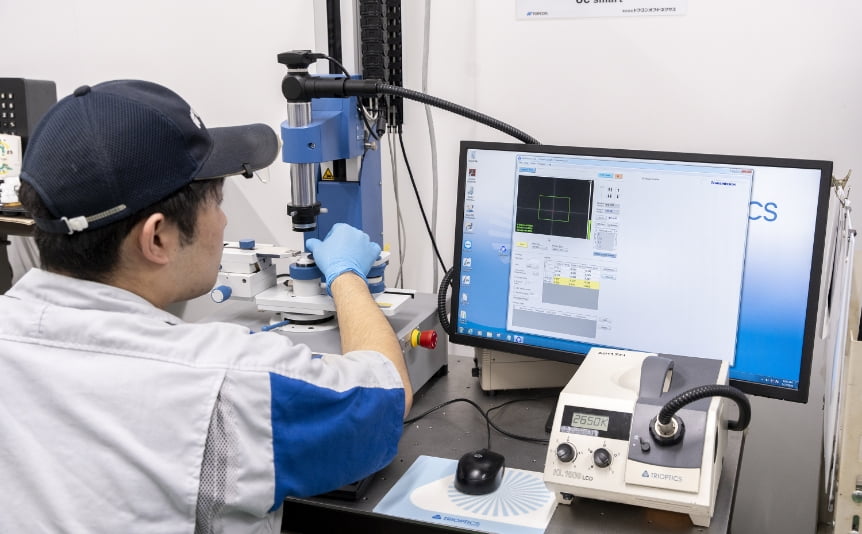

Eccentricity

measuring machineThis eccentricity measuring machine by Trioptics makes precise eccentricity measurement possible, achieving stable product performance and provides high reliability particularly for products that require precision.

-

Inspection devices With three ZYGO interferometers installed, we have a strict quality control system in place. By measuring minute surface irregularities and optical errors with a high degree of precision, we guarantee product accuracy that meets the advanced needs of our customers.

-

Joint verification

spaceWith three laboratories in place, we can respond quickly to customer design projects, such as by incorporating or correcting optical lenses immediately after we have manufactured them. We have prepared an environment that allows us to smoothly check product quality for the purpose of making final adjustments to prototypes and products in development. In turn, this allows us to flexibly respond to customer requests immediately.

Initiatives geared towards passing on optical glass skills and developing young employees

In manufacturing optical glass, passing on skills is an essential initiative for developing the industry and improving product quality. Skills that have been passed down from generation to generation, which have been honed over time by skilled engineers based on years of experience and knowledge, are passed on through education and training for their successors. This makes the manufacture of products requiring outstanding optical performance and the supply of stable quality possible.

Additionally, to enhance various forms of technical prowess, we also focus on obtaining national qualifications and technical certifications. Every year, we are seeing an increasing number of employees with these qualifications. Through these initiatives, we are succeeding in improving our technical prowess and stabilizing our product precision, and are building a firmer technical foundation by developing the next generation of engineers.

National qualification and technical certification holders

Wastewater management that underpins sustainable production activities

As part of our ESG (Environment, Society and Governance) initiatives, we have installed wastewater treatment facilities and wastewater purification equipment at our factory through which we perform thorough wastewater purification. We are endeavoring to minimize the impact of wastewater generated at our factory on the environment and to preserve the water quality in the surrounding area. Through these efforts, we are realizing sustainable production activities and facilitating harmony with the local community and natural environment.

PRODUCTS

-

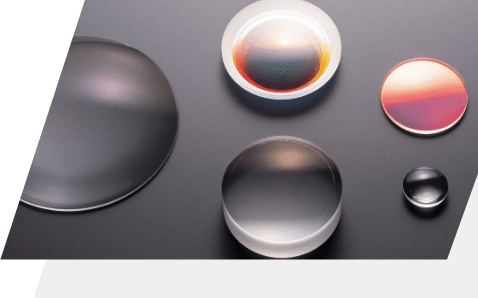

Spherical/aspherical processing

(Glass lenses)We produce spherical and aspherical lenses with outside diameters ranging from 3mm to 130mm from smaller lots on up. We carry out the integrated production that spans all processes from materials procurement to completion in our own factory. We are also capable of processing assorted processed glass materials such as FPL and other special materials that include germanium and fluorite. We have a well-equipped work environment centered on vapor deposition, fusion and inspection processes in place. Please contact us for details on whether we can accommodate your processing needs.

Click here for more info

-

A diverse array of optical components

The diverse array of precision optical components we process starts with corner cubes and extends to oblique prisms, right-angle prisms, rhombic prisms, Dach prisms, beam splitters, Porro prisms, flat glass plates, cylinder lenses, toroidal lenses, encoders, and patterning components.

Click here for more info

-

Optical modules

(Optical units)We also have a well-equipped environment in place for the embedding of lenses and the assembly of electronic equipment. Currently, we are bolstering our supply of optical module units for the likes of surveillance cameras, FA cameras, medical equipment, and surveying equipment.

As we do business with a number of suppliers, we are able to independently procure the various components necessary for the production of optical modules, including metal and electronic components.Click here for more info